Managing a large fleet of ageing assets has become a technical challenge faced by many electricity utilities in developed countries. Asset managers are increasingly interested in techniques that can help extend the lifetime of a transformer. Oil regeneration is one of such techniques. In this work, oil regeneration experiment was performed on a 6.4/0.4 kV retired distribution transformer which was in-service for 76 years to investigate the effect of oil regeneration on improving paper conditions.

Details of the transformer

|

Year of manufacture/retirement |

1936/2013 |

|

Rating (kVA) |

750 |

|

HV/LV (V) |

6400/405 |

|

Configuration, HV/LV |

Δ/Y |

|

Total Oil Volume (Liter) |

1273 |

|

Total weight including Oil (kg) |

4600 |

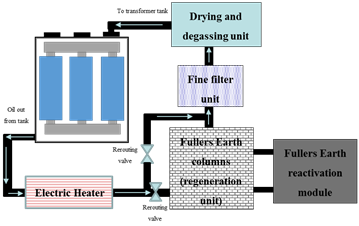

An oil regeneration unit particularly designed for indoor laboratory use with a capacity of 300 L/h, and with a single column of fuller’s earth was used for the study. Oil obtained from the bottom outlet of the transformer is sent through three stages including fuller’s earth reclamation, filtering and drying°assing, before being sent back to the tank from the top of the transformer.

|

|

|

|

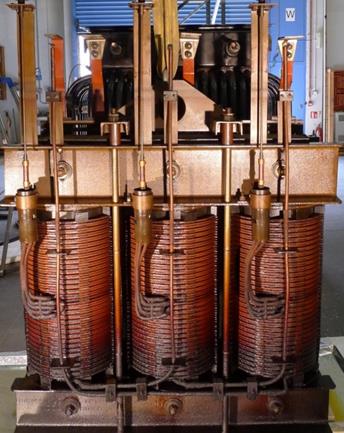

Front view of the core and winding assembly of 6.4/0.4 kV distribution transformer |

Schematic diagram of the oil regeneration system |

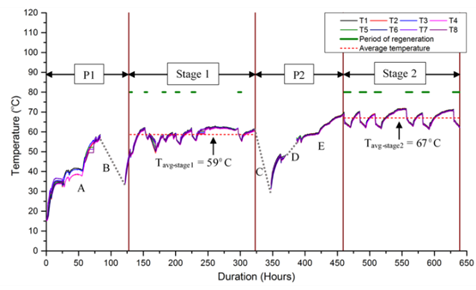

Oil regeneration was conducted in two stages, with the first stage aimed at ‘cleaning the oil’ and the second stage targeted at ‘cleaning the paper’. Oil samples were collected at regular intervals throughout the process and paper samples were obtained from the transformer before and after each oil regeneration stage. It was found that oil regeneration restores oil parameters, including moisture and acidity, similar to those of new oils at the end of stage 1. Analysis of paper samples indicated a reduction in paper moisture at the end of stage 2 by nearly 40%, while low molecular weight acids (LMA) in paper exhibited a reduction by around 30% on average. It is found that the extended oil regeneration period i.e. stage 2 is necessary to improve the paper condition and hence to reduce the page ageing rate. By the end of stage one acidity in oil reduced down to 0.05 mg KOH/g from nearly 0.74mg KOH/g oil. During the same stage water content in oil reduced from about 18 ppm to around 10 ppm.

|

|

|

Temperature profile during the regeneration experiment |

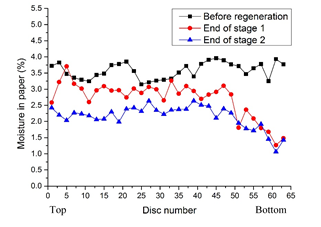

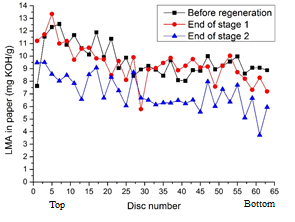

When considering the whole winding, stage 1 of the regeneration reduced the moisture content in paper by an average of 23% while the stage 2 reduced the moisture by a further 23% resulting in a nearly 40% reduction in the water content in paper. Initial LMA in paper before oil regeneration was found to be at an average of 10 mg KOH/g. The LMA in paper remained fairly unchanged at the end of stage 1. However, at the end of stage 2, this value reduced to an average of 7 mg KOH/g. This is a positive indication of the effectiveness of stage 2 in improving the condition of the paper insulation. According to CIGRE brochure 738 “Ageing of Liquid Impregnated Cellulose for Power Transformers”, it can be assumed that the frequency factor (A factor) in Arrhenius equation to be proportional to the multiplication of water and LMA content. Based on this assumption an average of 54.8% reduction in the ageing rate of paper due to the oil regeneration through both stage 1 and stage 2 was obtained compared to just a 25.9% reduction by regenerating oil through stage 1.

|

|

|

|

Profile of moisture in paper before regeneration, at the end of stage 1, and the end of stage 2 |

Profile of LMA in paper before regeneration, at the end of stage 1, and the end of stage 2 |

Although it is evident that extended oil regeneration is indeed effective to improve paper conditions, implementation of the process in practice requires fine tuning depending on various factors including transformer insulation structure, material ratio, off-line/on-line regeneration mode, etc. In addition, selection of transformers to be treated also requires a cost-benefit analysis. If the transformer insulation condition is too bad, potential life extension from the oil regeneration might be minimal; if the insulation condition is too good, oil regeneration can be a waste of resource.

Open access full paper can be accessed through – https://www.mdpi.com/1996-1073/12/9/1665